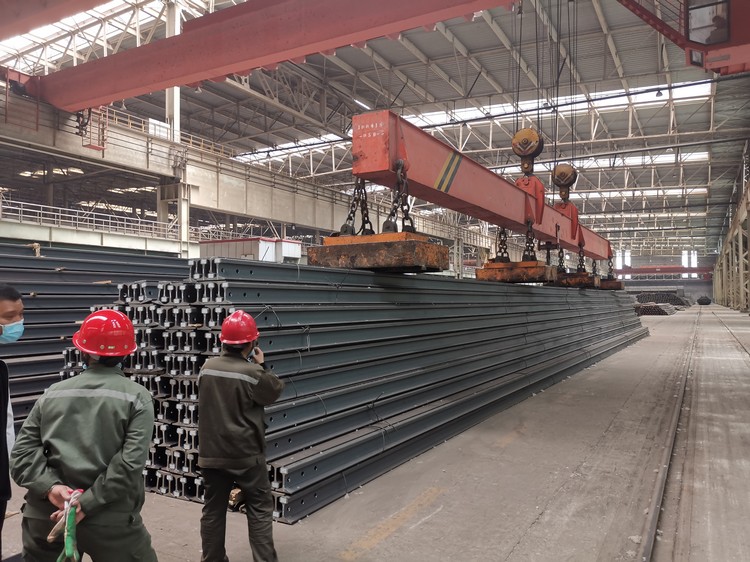

The safety and smooth operation of railways primarily depend on robust infrastructure equipment, which, like the skeleton of the human body, supports the entire transportation system. Rails and sleepers form the core components of the track. Modern railways predominantly utilize 60kg/m heavy-duty rails, primarily made of high-strength alloy steel. These rails possess wear-resistant and fatigue-resistant properties, capable of withstanding the repeated impacts of heavy-haul trains weighing tens of thousands of tons. Sleepers come in concrete and timber varieties, with prestressed concrete sleepers becoming the mainstream choice due to their superior stability and extended service life (up to 30+ years). These sleepers securely anchor rails through fastening systems, ensuring precise track geometry.

Turnouts serve as the “traffic hubs” of railway lines, enabling trains to change direction and tracks. Their quality directly impacts both train speeds and safety. High-speed turnouts employ seamless designs, with switch points cast from high-manganese steel. Controlled by electro-hydraulic point machines, they achieve switching response times of just 3-5 seconds, enabling smooth passage of 350 km/h high-speed trains. The subgrade and bridges/tunnels form the “foundation” of the track. The subgrade is constructed with layered, compacted fill material topped with geosynthetic materials to prevent soil erosion. Bridges predominantly feature prestressed concrete beams or steel truss structures, enabling them to span rivers and gorges across complex terrain. Tunnels employ techniques such as shotcrete support and secondary lining to ensure the stability and safety of passages carved through mountains. Some long tunnels are additionally equipped with specialized systems for ventilation, lighting, and firefighting.