The smooth operation of rail tracks relies on the “quiet dedication” of various precision fasteners. Though small in size, spikes, fishplates, and rail clips respectively undertake the critical tasks of securing sleepers, connecting rails, and limiting track movement. As core components ensuring stable track geometry and transmitting train loads, they serve as the “invisible cornerstone” of the track system.

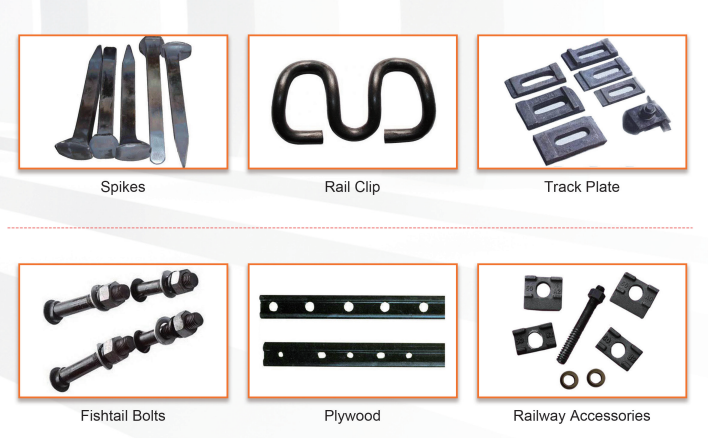

Rail spikes serve as the “binding link” between rails and sleepers. Their core function is to securely lock rails onto sleepers via fastening systems, preventing lateral displacement and longitudinal creep during train operation. Modern railways predominantly use threaded spikes made of high-strength alloy steel. Featuring threaded shanks paired with nuts and spring washers, these spikes achieve pull-out resistance exceeding 100 kN after installation. Traditional wooden sleeper tracks once used plain round nails. In modern concrete sleeper tracks, threaded spikes are anchored within pre-drilled holes using the sulfur anchoring method. This provides high anchoring strength and durability, resisting loosening risks caused by long-term train vibration. Additionally, specialized types like anti-drop spikes and insulated spikes are available, tailored for specific geological sections and electrified railways respectively. These ensure secure fixation while preventing electrical interference.

Fishplates, also known as rail joint plates, serve as the “critical bridge” for rail connections. They join the ends of two rails, replacing welding to achieve flexible rail joints. Made from materials matching the rails—typically high-manganese steel or low-alloy steel—they feature a fish-fin shape. Four to six sets of bolts pass through the rail joint holes, tightly bonding adjacent rails. Fishplates must not only transmit train loads but also accommodate thermal expansion and contraction of rails, hence incorporating elasticity in their design. High-quality fishplates feature precision-machined contact surfaces that achieve high conformity with rail joint ends. This reduces joint impact during train passage, lowers noise and wear, and facilitates rail removal and replacement during track maintenance, making them indispensable components in track laying and maintenance.

The guard plate serves as the track's “positioning guardian,” primarily installed on both sides of the sleeper or beneath the rail. It is categorized into gauge plates and plate bases. Gauge plates precisely control track gauge (standard gauge 1435mm) by adjusting thickness, preventing lateral rail displacement and ensuring wheel-rail contact accuracy. While plate bases support the plates and fasteners, distributing pressure to the sleepers to prevent localized stress concentration that could damage them. Plates are typically made of cast iron or composite materials, offering wear resistance and corrosion resistance. Their surfaces undergo rustproofing treatment to withstand harsh outdoor environments characterized by humidity and dust. On curved tracks or heavy-haul lines, thickened check plates are employed to enhance limiting strength, resist greater lateral thrust, and ensure long-term stability of track geometry.

Though each component—spikes, fishplates, and check plates—serves distinct functions, they form an interlocking fastening system: spikes secure rails to sleepers, fishplates connect rail sections, and check plates precisely control gauge. These “small components” shoulder significant responsibility. Their reliability directly determines track stability and safety, serving as a crucial safeguard for modern railways' high-density, high-speed operations. They exemplify the engineering wisdom that “details determine success or failure.”