Railroad Thermite welding is a track connection construction process with mature technology, it’s easy operate,efficient, and high-strength.

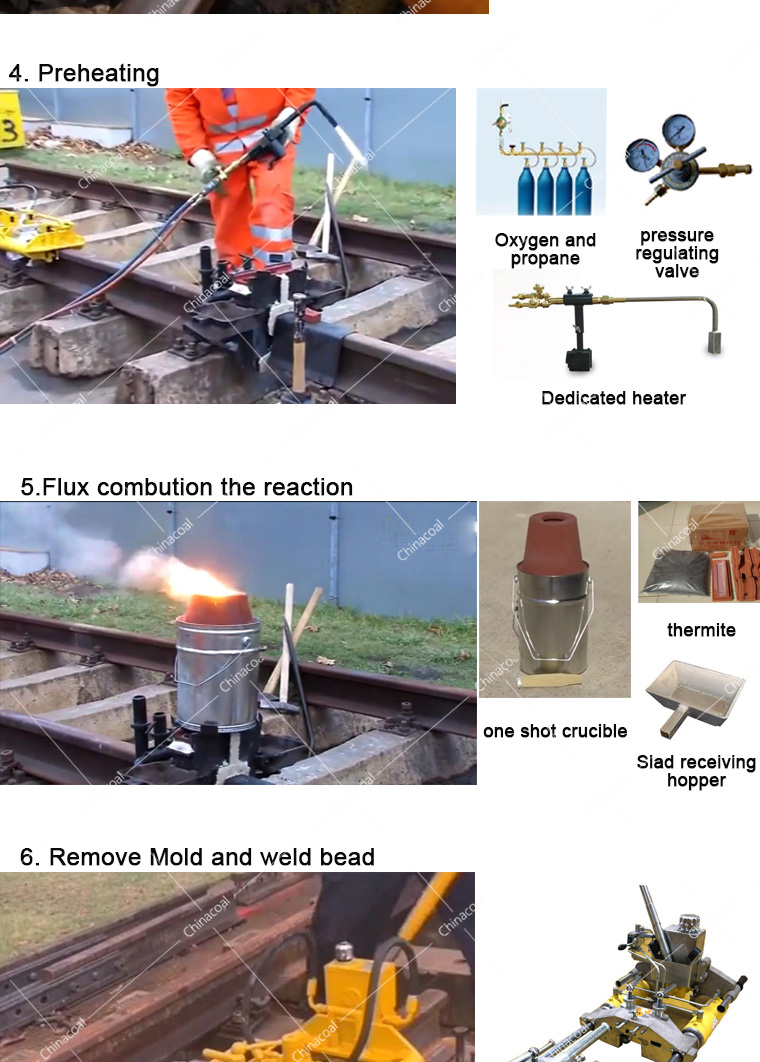

Rail thermite welding is a kind of thermite reaction by igniting Thermite flux which mixed with Aluminum powder, iron oxide and other metal additives in a special crucible at high temperature. During the reaction, a large amount of heat is released and Melt the alloy mixture to form molten steel.Because of its high density, molten steel sinks below, the slag generated by the reaction is relatively light and floats on the upper part, and the molten steel is filled with mold in a short time.

At the same time, the Thermite molten steel itself acts as a filler metal, crystallizes and cools together with the rail, and the two parts rails form a whole.

It can be used for kinds of rails including light rail ,QU heavy rail ,and abroad standard rails such as A150、CR73、UIC54、BS80A and so on .

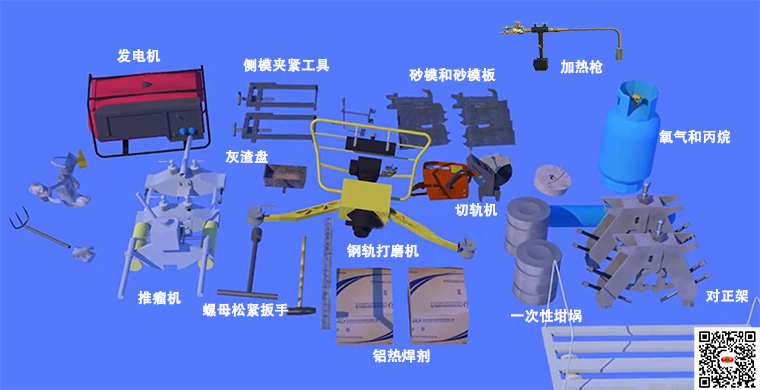

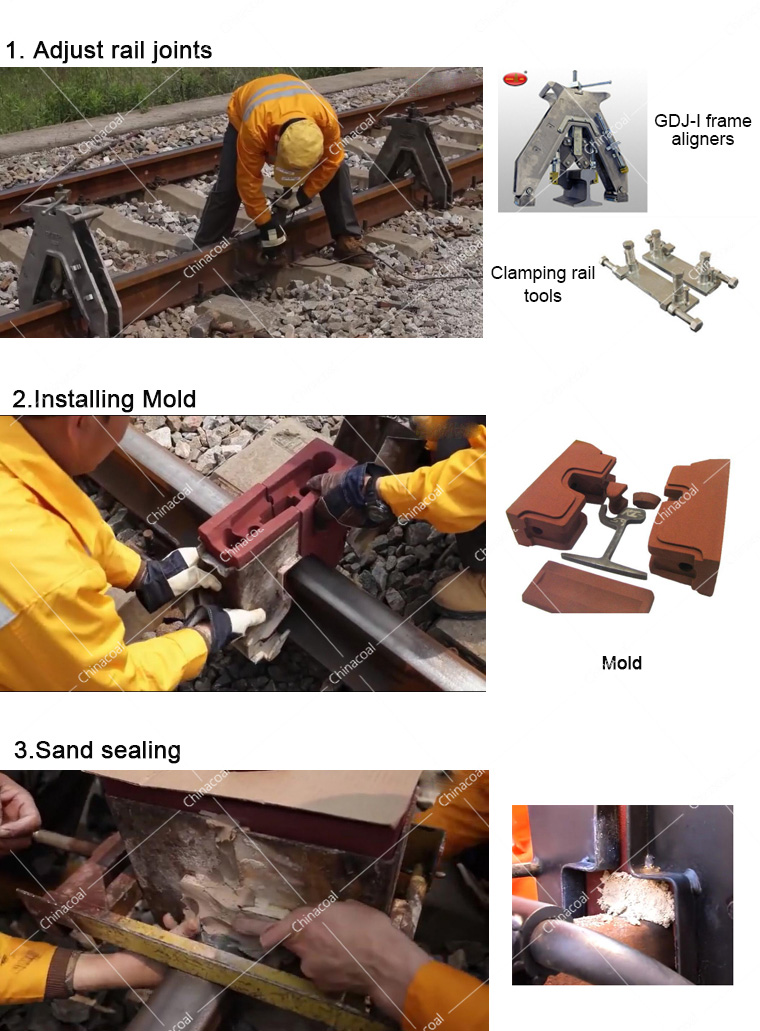

Preparation → Rail head cleanning and Rust removal→ adjusting Rail head distance → installation mold and clamping tools → Sealing → Preheating →Crucible installation → ignition → reaction → demoulding → remove mold and weld head → grinding.